Efficiency with a low environmental impact

The Cycle Begins

Continuous-cycle panel production requires a great deal of electricity and heat. For decades, the Fantoni Group has striven to reduce the impact of its energy consumption and has invested in the use of renewable sources, improving the efficiency of the company’s processes and reducing environmental impact.

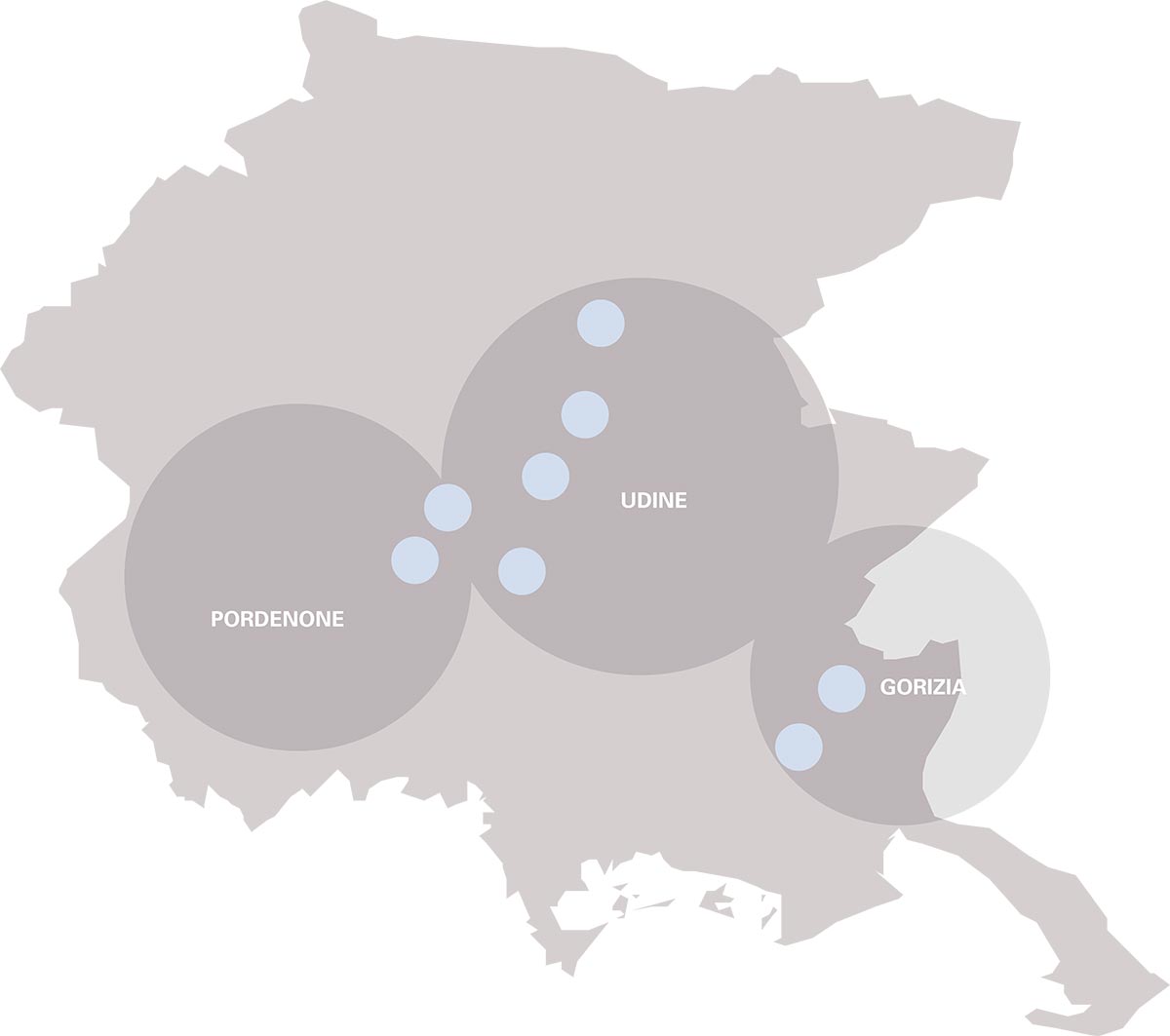

Energy and the Local Area

The Fantoni Group has eight hydroelectric power stations in Friuli Venezia Giulia. Harnessing a resource that is abundantly available in this region and has traditionally been used for productive purposes, our power stations put 60,000,000 kWh per year into the national energy grid, leading to an annual saving of over 30,000 tons of CO2.

Cogeneration and Biomass

Designed entirely by an in-house team of engineers and technicians, our systems make use of the best technologies available. The five cogeneration plants, which produce up to 30 MW of electricity, cover over 50% of the company’s electricity needs and achieve an overall energy efficiency of more than 85%. Three thermal power stations fully cover the factory’s heating needs: they are fuelled using wood waste generated from our processing plants and swarf from our furniture production.

UNI CEI EN ISO 50001:2018

In terms of energy efficiency and rational use of the resources, our Osoppo productive site has also implemented an UNI CEI EN ISO 50001:2018 Management System.

This not only represents a big step forward for the Group, but also another great starting point.

The ISO 50001 certificate demonstrates, indeed, the long-time and ongoing organization’s commitment to continual improvement in finding energy management solutions able to ensure better workflows and business competitiveness.